Facilities

Design

At Navtej Pressing and Engineering, we offer a wide range of design services to meet the specific needs of our clients. Our experienced team of designers and engineers use the latest software and tools to create customized designs that meet and exceed our clients' expectations.

We work closely with our clients to understand their requirements and provide innovative and creative design solutions. Our design services cover various areas, including tooling design, product design, and process design. We use advanced 3D modeling and simulation software to visualize the designs and identify potential issues before production, reducing time and cost.

Our design services include concept development, feasibility analysis, prototype design, and testing, as well as design optimization for cost and manufacturability. We have extensive experience in designing tools, dies, molds, fixtures, and other components for various industries, including automotive, aerospace, medical, and consumer products.

At Navtej Pressing and Engineering, we value collaboration, innovation, and quality, and we are committed to delivering exceptional design services to our clients. Our team works closely with our clients throughout the design process to ensure that their specific requirements are met and that the final design is reliable, efficient, and meets their expectations.

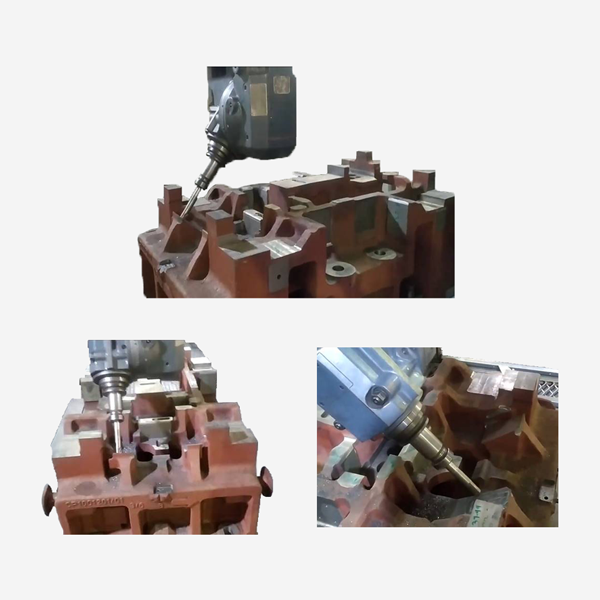

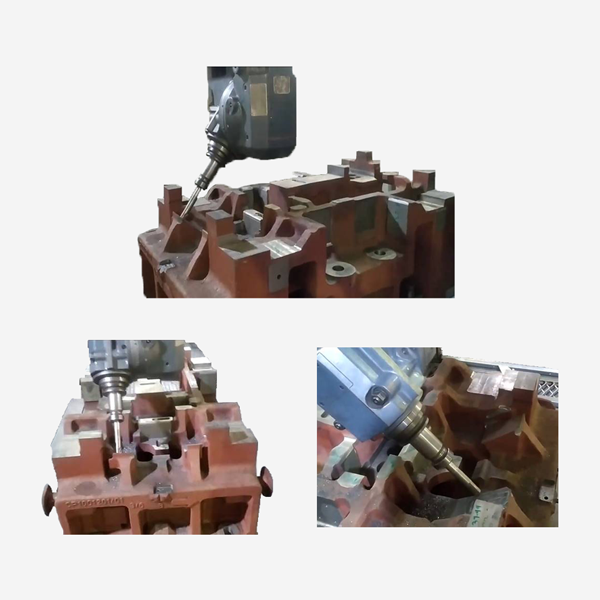

Manufacture

Navtej Pressing & Engineering is a leading manufacturer of high-quality tooling and components for various industries. Our state-of-the-art manufacturing facilities use the latest technology and equipment to produce precision parts and assemblies to meet our clients' exact specifications.

We specialize in sheet metal pressing, VMC machining, and thermoforming, and we have extensive experience in producing tooling, dies, molds, checking fixtures, and other components for various industries, including automotive, aerospace, medical, and consumer products.

Our manufacturing processes are designed for efficiency, quality, and repeatability, and we use advanced software and equipment to ensure that our products meet the highest standards of quality and reliability. We also have a strong focus on environmental sustainability, and we strive to minimize our impact on the environment through our processes and operations.

At Navtej Pressing & Engineering, we are committed to delivering exceptional manufacturing services to our clients. Our experienced team of engineers, technicians, and operators work closely together to ensure that every component we produce meets our clients' exact requirements and is delivered on time and on budget.

We value innovation, collaboration, and continuous improvement, and we are dedicated to staying at the forefront of the manufacturing industry.

Quality

Navtej Pressing & Engineering is proud to be an ISO 9001:2015 certified company. We prioritize quality and have all the necessary equipment to ensure the highest standards for our press tools, NVH molds, and checking fixtures. Our quality control measures include the use of Vernier calipers, hardness testers, and other advanced tools to thoroughly inspect and verify the quality of our products. We are committed to delivering tools and molds with zero defects, and we follow stringent quality systems to achieve this goal.

Tryout & devlopment

We have Tryout Presses ranging from 250T to 1000T at our Associated Partner's facility.